Revolutionizing Soil Thermal Conductivity Testing with ConeTec’s Thermal CPTu Module

The accurate in-situ characterization of soil thermal conductivity is important for the design of buried utilities and other subsurface structures that rely on the transmission of heat through the soil, such as power cables. Traditionally, measuring thermal conductivity has required lab testing methods or complex field setups, both of which can be time-consuming, costly, and often lacking precision and repeatability.

ConeTec’s new Thermal CPTu Module changes this.

1.0 A Groundbreaking In-Situ Solution

ConeTec’s patented Thermal CPTu (Cone Penetration Testing) Module measures soil thermal conductivity directly in-situ by taking the standard needle probe method and integrating this immediately behind the cone penetrometer. This eliminates or reduces the need for slow, expensive lab tests and delivers high-confidence data with targeted in-situ testing of minimally disturbed soil and excellent soil-to-sensor contact.

ConeTec’s Thermal-CPTu module produces a comprehensive understanding of soil behaviour, groundwater conditions, and thermal conductivity together at target depths from a single CPTu or Seismic-CPTu.

2.0 Why It Matters: Critical for Energy Infrastructure Design

Soil thermal conductivity is a key parameter in the design of underground infrastructure where heat transfer through the ground is a major concern. Applications include:

- Cable route and pipeline surveys (marine & land-based)

- Underground transmission lines

- Data center geotechnical investigations

- Geothermal systems and energy piles

The Thermal CPTu Module provides designers with accurate in-situ thermal conductivity data from depths where it matters most, helping to improve the design and performance of thermal-based foundations and utility systems.

3.0 HOW IT WORKS: PROVEN SYSTEM WITH DATA RELIABILITY

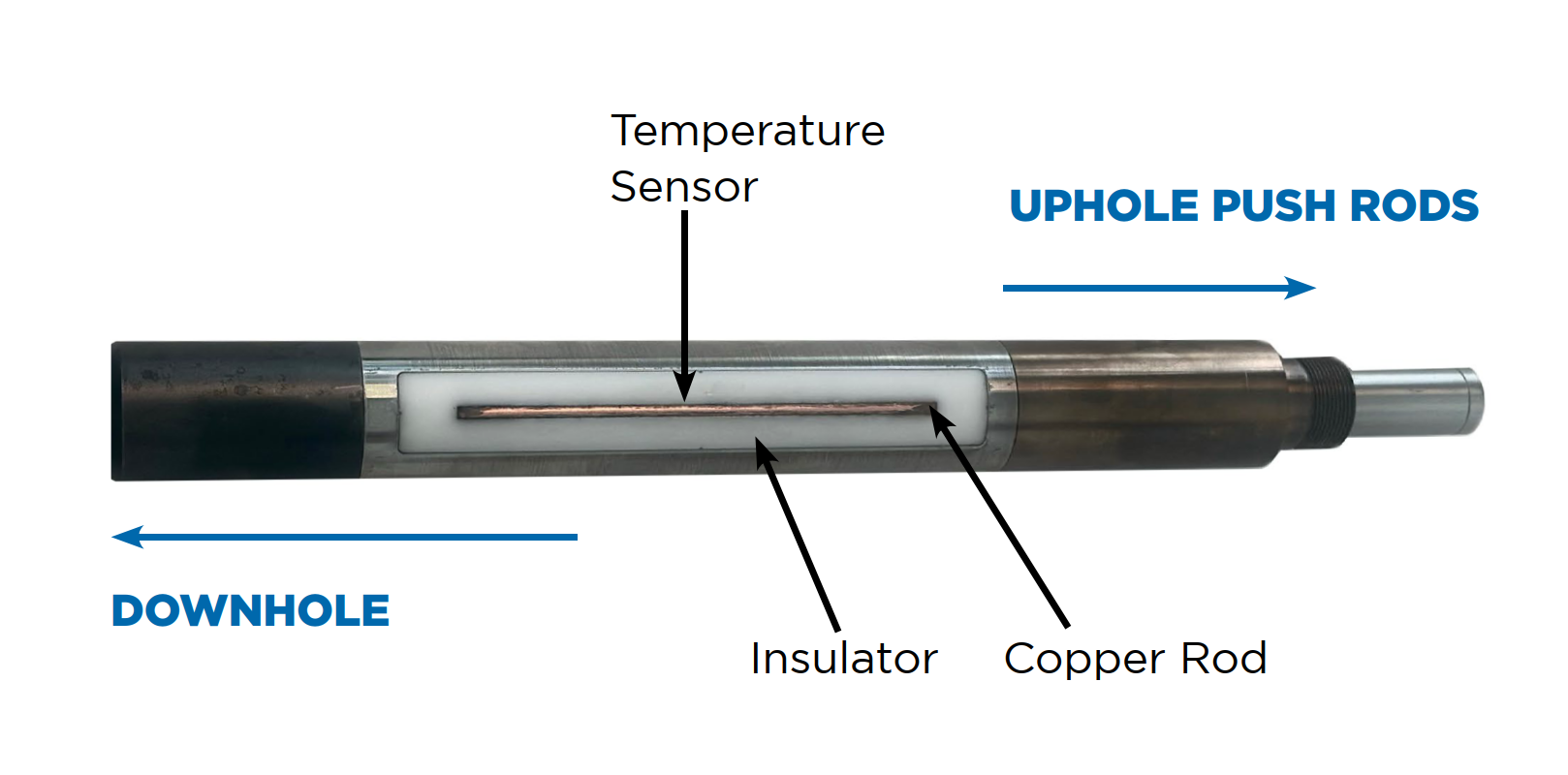

The Thermal-CPTu Module developed by ConeTec was inspired by the simplicity of the commonly used Thermal Needle Probe Test Method (ASTM D5334). The ConeTec module combines the concept of this linear heat source, embedding it into the side of a CPTu probe for simultaneous deployment.

The module collects CPTu/Seismic CPTu data and measures the thermal conductivity of soil using a 16 cm long copper heating element. ConeTec performs calibration of the thermal module using a multi-point model to account for the module’s geometry.

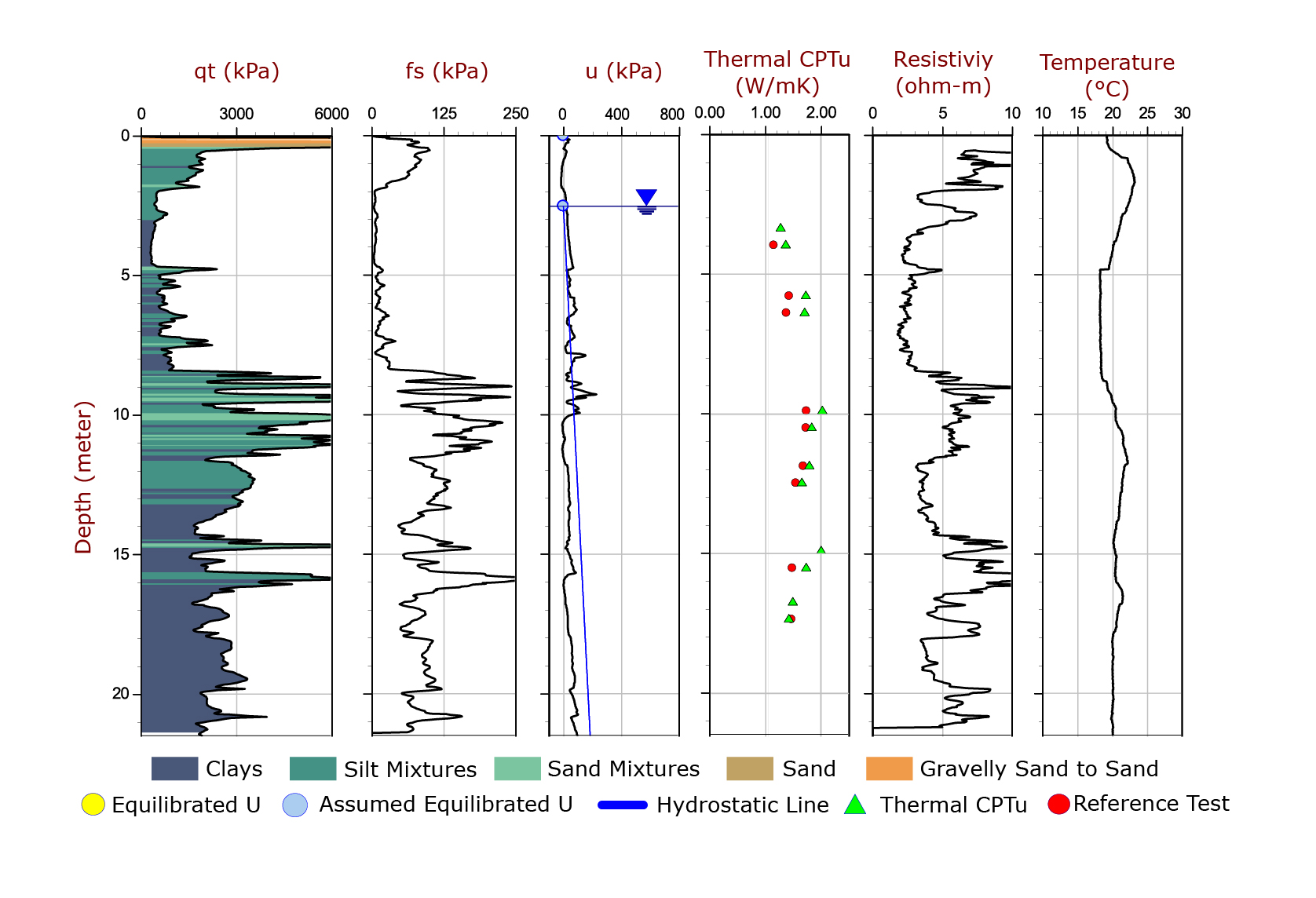

During development of this module, both laboratory and in-situ field testing were conducted to prove both the design and methodology. In the example plot below, in-situ thermal conductivity results, lab-based thermal conductivity results and CPTu data are presented. Current CPTu thermal tests show strong agreement with reference needle probe test data. The calibration range of the Thermal CPTu module supports saturated or unsaturated conditions for a range of soil types and is robust for deployment in the same soils that are suitable for the CPTu.

Figure 1: CPTu plot with thermal conductivity results from both (a) ConeTec’s thermal module and (b) the traditional needle probe method (Reference Tests)

4.0 Testing Procedure: How to Collect Data

The Thermal CPTu Module follows a simple and efficient testing process designed for seamless integration into standard CPTu operations. The steps below outline the procedure for collecting in-situ thermal conductivity data:

- Push the tool to the desired test depth while collecting CPTu/Seismic CPTu data.

- After reaching the target test depth, wait approximately 15 minutes, or until temperature stabilization is observed, to allow thermal equilibrium following frictional heating during penetration.

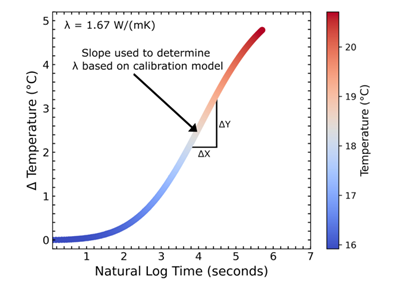

- Perform the thermal conductivity test – apply heat to the module’s element while measuring the temperature of the adjacent soil.

- Advance the tool to the next test depth and repeat steps 2 & 3. The overall duration for steps 2 & 3 of the thermal testing sequence is approximately 15 minutes.

Figure 2: Thermal conductivity is calculated from the slope of temperature rise over log time

5.0 Benefits: Fast, Repeatable, Field-Ready

Designed for efficiency and reliability, the Thermal CPTu Module delivers consistent, high-quality in-situ data from the field. Key advantages include:

- Fast: One complete thermal conductivity testing sequence requires only 20 minutes.

- Repeatable: The integrated CPTu method ensures operator-independent results with consistent soil contact.

- Reliable: Results are automatically processed, generating thermal conductivity plots in minutes. Excellent contact with soil ensures accurate results without sample disturbance.

- Verifiable: Optional side-by-side testing using traditional field or lab thermal methods can be performed for comparison.

6.0 Let’s Collaborate!

ConeTec is actively seeking industry partners to advance the development of this new technology. If you're working on projects involving underground utilities or energy systems — and want to streamline your testing program while improving your thermal conductivity dataset – contact us to explore opportunities using this new tool.

Contact your nearest ConeTec office to learn how we can work together and integrate Thermal Conductivity CPTu into your next project.

Note: ConeTec retains all intellectual property developed from the use of the Thermal CPTu Module. Any findings may be published only with written permission or in anonymized format, in accordance with client confidentiality agreements.

For more information contact us at www.conetec.com/contact

Resources:

Publication: Characterizing soil thermal conductivity in situ: development of a novel cone penetration test module | ISSMGE

QUICK LINKS